Powering Innovation Through Clarity and Performance

In today’s fast-evolving industrial and healthcare landscape, material science plays a defining role in shaping safety, performance and design flexibility. Among various polymer materials, PVC Transparent Compounds stand out as one of the most versatile and impactful innovations. They combine exceptional clarity with mechanical strength, durability and cost efficiency, enabling their use across a wide range of industries.

From medical tubing to consumer packaging, automotive interiors and electrical insulation, transparent PVC compounds have transformed how manufacturers approach product design. With decades of experience in polymer formulation, DEV Polymer, a Delhi-based company producing over 10,000 tons annually, continues to lead this revolution with cutting-edge compound technology.

Understanding PVC Transparent Compounds

PVC Transparent Compounds are specially formulated blends that provide crystal-clear visibility, flexibility and strength. Unlike standard opaque PVC used in insulation or sheathing, these transparent grades are made using specialized plasticizers and stabilizers that retain optical clarity while ensuring long-term durability and chemical stability. The result is a compound that offers:

-

Excellent optical transparency

-

High flexibility and tensile strength

-

Strong resistance to UV light and heat

-

Compatibility with extrusion and moulding processes

These properties make transparent PVC a preferred material for applications where both aesthetics and performance are equally important.

The Science Behind Clarity and Strength

PVC, in its natural form, is a semi-rigid thermoplastic. Achieving clarity and flexibility requires precise compounding. Manufacturers like DEV Polymer use high-quality raw materials and advanced filtration systems to remove impurities and maintain purity throughout the process. Each batch typically includes:

-

High-purity PVC resins for structural integrity

-

Non-reactive plasticizers for improved softness and flexibility

-

Thermal stabilizers that prevent yellowing during processing

-

Lubricants and additives to enhance surface finish and transparency

Through strict formulation control, DEV Polymer creates transparent compounds that balance optical brilliance with mechanical toughness, ensuring both visual appeal and dependable performance.

Applications in the Consumer Goods Industry

In consumer markets, product design increasingly values transparency and visual appeal. Transparent PVC compounds allow manufacturers to deliver products that are both functional and visually engaging.

-

Packaging Solutions: Transparent PVC compounds are extensively used by manufacturers to create blister packaging, food-grade containers and retail display boxes. These high-quality compounds provide excellent clarity, durability and resistance to moisture and oils, ensuring the final packaging products remain visually appealing, long-lasting and protective, giving brands a distinct edge on retail shelves.

-

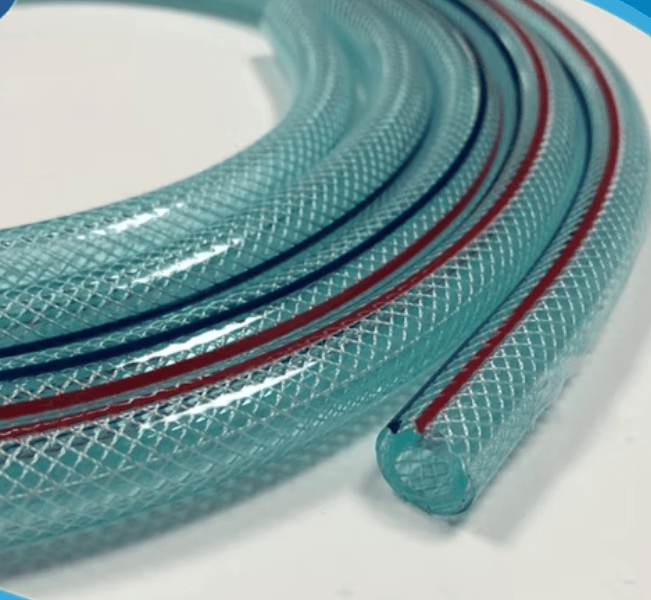

Household and Lifestyle Products: In household and lifestyle products, materials like flexible hoses, suction pipes, shower curtains, table covers, furniture edge trims and protective sheets are often crafted using PVC transparent compounds. Their durability and aesthetic appeal allow manufacturers to design sleek, long-lasting and affordable consumer goods that blend functionality with modern style.

-

Electrical and Lighting Components: In lighting systems and wiring accessories, transparent PVC provides safety and aesthetic advantages. It allows easy visual inspection of conductors and connectors. DEV Polymer’s clear insulation compounds are particularly popular in LED strips, decorative lights and transparent cable sleeves used in homes, offices and vehicles.

Transforming the Medical and Healthcare Industry

The medical field demands materials that ensure safety, sterility and reliability. Transparent PVC compounds have become a cornerstone material due to their biocompatibility, flexibility and clarity.

-

Medical Tubing and Catheters: In the medical field, IV sets, catheters, oxygen tubes and suction devices rely on materials that ensure safety and precision. The clarity of these components allows healthcare professionals to easily monitor fluid flow and identify blockages or air bubbles. DEV Polymer’s medical-grade transparent compounds are non-toxic, phthalate-free, kink-resistant and fully compatible with ETO, gamma and steam sterilization methods, ensuring reliability and hygiene in every application.

-

Blood and IV Containers: PVC transparent compounds are ideal for blood bags and infusion bottles because they combine clarity with chemical inertness. They allow clear visualization of fluids while maintaining a sterile environment free from contamination.

-

Diagnostic and Disposable Equipment: From face masks and connectors to fluid chambers and drainage systems, transparent PVC components enable accurate monitoring and precise functionality. DEV Polymer ensures that its medical-grade formulations maintain consistent transparency, strength and safety compliance across production batches.

Advantages of Transparent PVC Compounds

Transparent PVC offers a range of performance and economic advantages that make it the preferred material for many industries.

-

High Clarity and Aesthetic Value: Maintains clear visibility without fogging or discoloration.

-

Durability: Provides excellent impact resistance and flexibility even under harsh conditions.

-

Cost-Effectiveness: More affordable and easier to process than alternative materials such as TPU or silicone.

-

Versatility: Suitable for extrusion, injection moulding, calendaring and blow moulding.

-

Sterilization-Friendly: Supports multiple sterilization processes required for medical devices.

-

Regulatory Compliance: Can be formulated to meet RoHS, REACH and ISO standards.

These features make PVC transparent compounds an ideal solution for industries seeking balance between aesthetics, safety and performance.

DEV Polymer’s Competitive Edge

DEV Polymer stands as one of India’s most trusted names in PVC compounding. With a 10,000+ ton annual production capacity, we combine scale with innovation.

What Sets DEV Polymer Apart?

-

State-of-the-art automated compounding and filtration systems

-

Dedicated R&D lab for product customization

-

Certified quality management

-

Experienced technical team for end-use optimization

Each transparent PVC batch undergoes rigorous clarity, tensile and heat-resistance testing to ensure superior consistency and reliability. This attention to detail has positioned DEV Polymer as a preferred partner for leading cable, medical and packaging manufacturers across India.

Commitment to Sustainability

With environmental responsibility becoming a global priority, DEV Polymer is developing eco-friendly transparent PVC formulations that support a circular economy. The company focuses on:

-

Phthalate-free plasticizers

-

Low-VOC stabilizers

-

Recyclable polymer designs

These efforts align with global sustainability goals and reflect DEV Polymer’s mission to innovate responsibly while maintaining uncompromised quality.

Conclusion

PVC Transparent Compounds have transformed both consumer and medical manufacturing, offering a powerful combination of clarity, flexibility, safety and cost efficiency. They bridge the gap between functionality and aesthetics, making them indispensable in today’s competitive industries.

As a pioneer in polymer manufacturing, DEV Polymer continues to innovate with transparent PVC compounds that meet international standards, empower industries and redefine material excellence for the modern world.